Fertilizers are a very important part of modern agriculture--providing nutrients to crops. Understanding the process of how fertilizers are made can help enhance understanding of better decision making for sustainable farming.

The production of fertilizer begins with the acquisition of raw nutrients (nitrogen, phosphorus, potassium), which are supplied in raw form - either mined or synthesized - and then may be "weathered" chemically to induce their availability to plants. Various processes like blending, granulating and sometimes coating for controlled release is often employed in the production of fertilizer.

Now, when we consider how nourishers are made, nitrogen typically is produced using the Haber-Bosch process which converts atmospheric nitrogen into ammonia for subsequent processing to urea or ammonium nitrate, which is both a very common nitrogen product.

So how are artificial fertilizers made? Artificial or chemical fertilizers are manufactured via industrial chemical reactions. An example is where phosphate rock is treated with sulfuric acid to make superphosphate. Products are scientifically designed for direct availability to a plant.

Introduction: Why Knowing How Fertilizers Are Made Matters

It is important for farmers, gardeners, and consumers who care about food and its quality and the environment to know how fertilizers are made. Fertilizers are formed from natural or synthetic components into nutrients that are used for crop production. If you understand the fertilizer, you can make better decisions, for example; better use will produce better crops.!

- Better understanding will lead to responsible use.

- Sustainable Practices begin with understanding where it came from.

Understanding the Link Between Fertilizer and Crop Yield

Fertilizers are the foundation of modern agriculture.; they are a direct way to replace nutrients naturally found in the soil and fertilizers themselves directly influence growing and harvest capacity.

- Nitrogen promotes vegetative, leafy growth and enhances vigor.

- Phosphorus builds roots and flowering & fruiting capacity.

- Potassium improves stamina and yield.

Once you understand fertilizer, how it is made, you can select the right type for your farming context, organic, inorganic, fast-releasing, or slow-releasing.

The Science Behind Soil Nutrition and Plant Growth

To understand the process of how are synthetic fertilizers, you must first understand the three main ingredients - ammonia, phosphoric acid and potassium salts. Those ingredients are chemically changed to create high concentrations.

- Nitrogen (N): From the air (Haber-Bosch) process.

- Phosphorus (P): Removed from phosphate rocks with acids.

- Potassium (K): Mined as potash and processed to ensure it is ready to be used by your plants to grow.

These ingredients are combined and granulated into usable products, such as urea or DAP (di-ammonium phosphate) for fast acting soil enhancement.

From Factory to Field: Fertilizer’s Journey

The last step of how are inorganic fertilizers made, is packaging and shipping. These fertilizers are meant to be used on a wide scale, thus they are delivered with a concentrated amount of nutrients in an easy to apply form.

- Common outputs include granules, liquids, and coated pellets.

- Distribution is planned and executed to minimize nutrient losses.

- Application patterns may include manual spreaders or as complex as precision sprayers.

Fertilizers must travel a long way from large industrial plants to farmers, while providing the necessary nutrients for plants to thrive.

Fertilizer: How It's Made Step by Step

Fertilizers are a key driver of modern agriculture, but few understand the actual process of how fertilizers are made. From mining raw nutrients to packaging finished products, each step is carefully designed to ensure crops get the nutrients they need in the most efficient way possible.

Gathering Raw Materials: Nitrogen, Phosphorus, Potassium

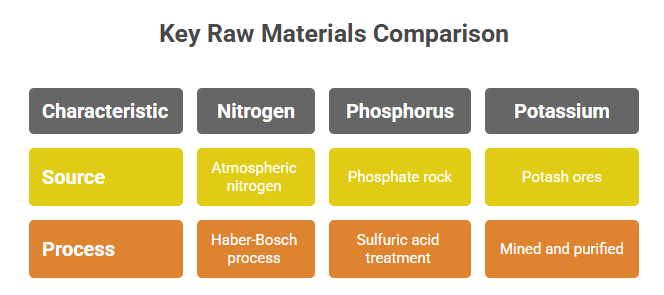

The process begins with the extraction of the three primary nutrients that support plant growth: nitrogen (N), phosphorus (P), and potassium (K). These ingredients form the NPK foundation of all major fertilizers.

Key Raw Materials:

Nitrogen fixation requires significant energy and synthetic chemistry.

- Phosphates are usually extracted through large-scale mining operations.

- Potassium is obtained through evaporation or mining from salt-rich beds.

Understanding how are inorganic fertilizers made starts with appreciating the energy and materials involved in raw nutrient sourcing.

Blending and Granulation: Creating Uniform Fertilizer Pellets

Once raw materials are processed into usable chemical forms, they must be carefully blended to produce the correct nutrient ratios (e.g., 10-10-10 or 20-5-10).

The Granulation Process:

- Blending: N, P, and K compounds are mixed in specific ratios.

- Granulation: The mix is sprayed with water and rolled into uniform pellets.

- Drying: The granules are dried to reduce moisture and improve shelf life.

- Coating (optional): Slow-release or anti-caking coatings may be applied.

This step ensures consistent nutrient distribution in every pellet, which is critical to both large-scale farming and smallholder crop management. This is where fertilizer how it's made truly comes to life in industrial plants.

Packaging and Distribution for Farm Use

After granulation, fertilizers are cooled, tested for quality, and packed into sacks or bulk containers for shipping. Packaging is optimized based on usage—small bags for retail gardening, large sacks or tankers for commercial agriculture.

Farm-Ready Delivery:

- Bag sizes range from 5 kg to 50 kg, depending on end-user.

- Liquid fertilizers are sealed in drums or IBC tanks.

- Granular products are stacked and palletized for logistics efficiency.

How are artificial fertilizers made doesn't end with chemical synthesis—it includes logistical planning to get the right product to the right farmer at the right time.

How Are Artificial Fertilizers Made in Modern Factories?

Understanding how fertilizers are made—especially synthetic ones—sheds light on the advanced science and engineering behind crop nutrition. Modern fertilizer plants use precise industrial processes to produce nutrients in bulk, ensuring reliable results for global agriculture.

Industrial Chemical Processes and Reactions

Artificial fertilizers are the result of highly controlled chemical reactions that convert natural elements into plant-available forms.

Key Reactions Include:

- Haber-Bosch Process (for Nitrogen): Converts atmospheric nitrogen (N₂) and hydrogen (H₂) into ammonia (NH₃) under high pressure and temperature with an iron catalyst.

- Sulfuric Acid Reaction (for Phosphorus): Phosphate rock is treated with sulfuric acid to produce phosphoric acid—used to make superphosphates.

- Potash Refining (for Potassium): Potash ores are mined and purified through flotation or crystallization.

These methods form the backbone of how are artificial fertilizers made, providing the NPK foundation found in nearly every bag of fertilizer.

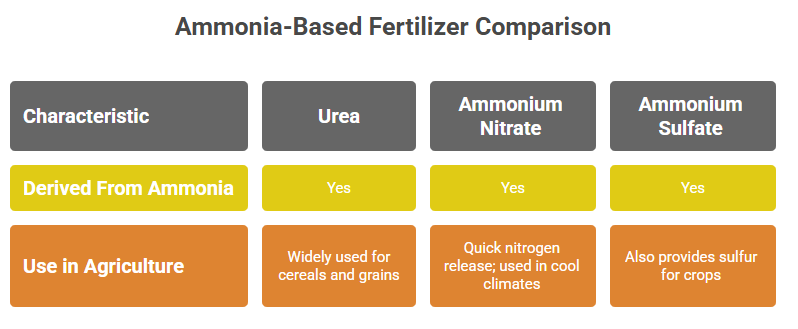

The Role of Ammonia in Nitrogen-Based Fertilizers

Ammonia is the key starting point for most nitrogen fertilizers and plays a central role in how fertilizers are made globally.

Ammonia-Based Products:

Ammonia is often injected directly into the soil in gaseous or liquid form.

- It's extremely efficient but requires safe handling and storage due to volatility.

This highlights fertilizer how it's made in modern nitrogen plants and the pivotal role ammonia plays.

Large-Scale Production Techniques and Safety

Modern factories are equipped with automated systems for blending, reacting, cooling, and packaging fertilizers at industrial scale.

Production Highlights:

- Continuous Flow Systems: Allow 24/7 operation for mass output.

- Granulators & Coaters: Ensure uniform pellet size and controlled release.

- Environmental Controls: Include scrubbers and filtration units to reduce emissions.

Safety Measures:Understanding how are inorganic fertilizers made also involves knowing the safety protocols to manage chemical risks and maintain consistent quality.

How Are Inorganic Fertilizers Made for Mass Agriculture?

Inorganic fertilizers are vital to global food production. Understanding how fertilizers are made, particularly how are inorganic fertilizers made, helps explain their efficiency, composition, and large-scale impact on farming. These synthetic fertilizers are engineered to deliver specific nutrients quickly and uniformly across vast fields.

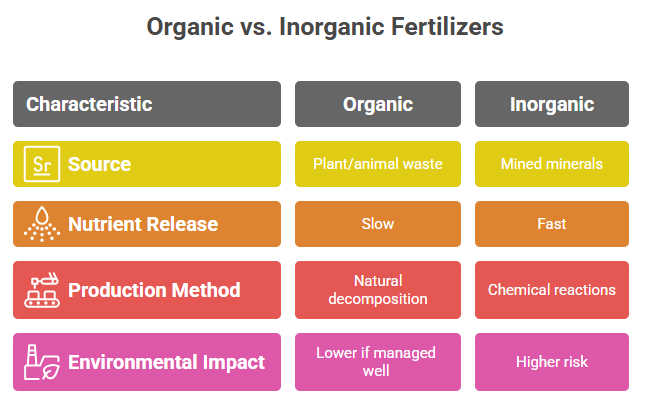

Differences Between Organic and Inorganic Fertilizers

Inorganic (chemical or synthetic) fertilizers differ significantly from organic fertilizers in source, composition, and action.

Comparison Table:

The difference in how fertilizers are made lies in the precision and scalability of inorganic fertilizer manufacturing, which suits large-scale agriculture.

Common Ingredients in Inorganic Formulations

Mass-produced inorganic fertilizers are designed for efficiency and ease of use. They typically contain three essential macronutrients: nitrogen (N), phosphorus (P), and potassium (K), often referred to as NPK.

Key Ingredients:

- Nitrogen Sources: Urea, ammonium nitrate, ammonium sulfate

- Phosphorus Sources: Superphosphate, diammonium phosphate (DAP)

- Potassium Sources: Potassium chloride (MOP), potassium sulfate

These materials are processed chemically in factories to form granular, liquid, or prilled fertilizers. This industrial approach is at the heart of fertilizer how it's made in the modern world.

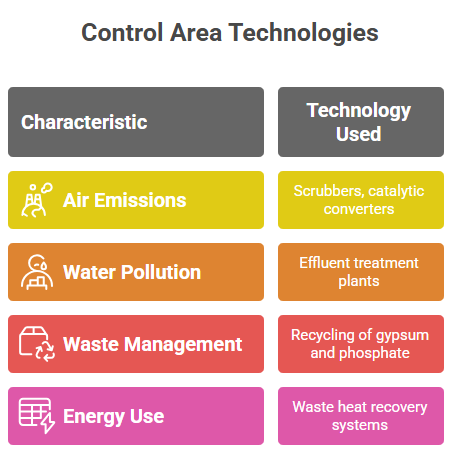

Environmental Controls in Inorganic Fertilizer Plants

While efficient, inorganic fertilizer manufacturing poses environmental challenges. Therefore, plants are equipped with advanced systems to minimize pollution and ensure safety.

Common Environmental Control Systems:

These systems ensure that how are artificial fertilizers made aligns with sustainability standards, despite the industrial nature of the process.

Innovations in Fertilizer Manufacturing

Modern agriculture continues to evolve, and so does how fertilizers are made. From how are artificial fertilizers made to precision-focused developments, the fertilizer industry is adopting cutting-edge technologies to boost efficiency and sustainability. These innovations address the environmental footprint and nutrient delivery of inorganic fertilizers while improving yields.

Precision Blending and Coating Technologies

One of the most notable changes in fertilizer how it's made is the introduction of precision blending and advanced coating methods. These technologies ensure each granule delivers a specific nutrient profile customized for crop and soil needs.

Key Benefits:

- Nutrient Uniformity: Reduces over- or under-fertilization

- Tailored Formulations: Specific blends for different crops or stages

- Minimized Losses: Coatings reduce volatilization and leaching

This innovation is particularly crucial in how are inorganic fertilizers made because it increases the efficiency of synthetic nutrients without sacrificing plant performance.

Low-Emission and Sustainable Manufacturing

Environmental concerns have led to cleaner, greener practices in the fertilizer industry. Today, how fertilizers are made includes low-emission systems and energy-saving designs to cut down on greenhouse gases.

Sustainable Manufacturing Practices:

- Carbon Capture Systems: Installed in ammonia production units

- Waste Recycling: Byproducts like phosphogypsum are reused

- Energy-Efficient Reactors: Reduce fossil fuel dependency

These practices are transforming how are artificial fertilizers made—balancing industrial productivity with planetary responsibility.

Smart Fertilizers and Controlled Release Systems

Smart fertilizers represent a major shift in how fertilizers are made today. These advanced formulations respond to environmental cues like temperature and moisture to release nutrients only when needed.

Features of Smart and Controlled Release Fertilizers:

- Polymer Coated Granules: Release nutrients slowly over time

- Nano-Fertilizers: Boost uptake at a cellular level

- Sensor-Integrated Fertilizers: Still in development, but promising for real-time monitoring

These systems redefine fertilizer how it's made by maximizing impact per dose and reducing waste—especially important in how are inorganic fertilizers made on a mass scale.

FAQs

Q1. How fertilizers are made from basic raw materials?

Fertilizers are made using raw materials like nitrogen, phosphorus, and potassium sourced from natural deposits or synthesized through chemical processes.

Q2.What does 'fertilizer how it’s made' typically include?

Fertilizer how it's made covers sourcing raw nutrients, chemical blending or organic processing, granulation, and packaging for distribution.

Q3.How are artificial fertilizers made in large quantities?

How are artificial fertilizers made involves industrial-scale chemical reactions—like the Haber-Bosch process for ammonia—followed by blending and granulation.

Q4.How are inorganic fertilizers made compared to organic ones?

How are inorganic fertilizers made using synthetic chemicals, while organic fertilizers are produced from natural composts, manures, and bio-waste.

Q5.Are synthetic and inorganic fertilizers the same?

Yes, synthetic fertilizers are a type of inorganic fertilizers, both manufactured through industrial chemical processes for high nutrient concentration.

Conclusion: Understanding Fertilizer Production to Make Smarter Farming Choices

Knowing how fertilizers are made gives farmers the power to choose inputs that align with both yield goals and environmental responsibilities. Whether you're using conventional or modern methods, understanding the origins and science behind fertilizers can enhance decision-making on the field.

Fertilizers play a crucial role in modern agriculture, but not all are made alike. From how are artificial fertilizers made in massive chemical plants, to how are inorganic fertilizers made through mineral-based processing, and even down to how raw materials are transformed into crop-ready nutrients, the journey matters.