Biofertilizers are live inputs which means that their long-term viability depends on how they are stored before they are used. To prolong the remaining viability once you are in possession of them, always keep products cool (15–25 °C), dry (< 60 % RH), and out of sunlight; putting pallets on wooden slats protects moisture wicking from the floor, and opaque airtight containers will mitigate fluctuations in UV and oxygen. Silica-gel packs in opened bags are a second-level precaution that can mitigate viability.

Longevity is also based on systematic treatment. Put a date on every batch; use a first in first out system so CFU counts remain in the 10⁷ g⁻¹/mL⁻¹ action area on a rolling in-home viability check (plate count or enzyme dip-stick) every 6 weeks, which lets you check the condition (and that biofertilizer storage and shelf life have remained in) so you will be close to optimal.

While they are only minor, power failures on fans, and a simple insulated ice chest to handle biofertilizers in the field can also be extra precautions to mitigate losses from shortcomings beyond your ability to control storage, leading to biofertilizers delivering globally active microbes to the seed trench. Follow these simple recommendations to help lock in reliable yields, richer soils, and lower bills for synthetic fertilizer from harvest to harvest.

Introduction: Why Proper Biofertilizer Storage Matters

Biofertilizers are live inputs, and when you purchase any colony forming unit (CFU), you are investing in soil health and nutrient use efficiency. That being said, the microbes only remain effective if the storage of biofertilizers protects them from the factors of heat, moisture, and light. Failing to consistently protect the microbes, even for a short period of time, can mean observed viable counts drop by 50% in a very short time converting an exceptional inoculant into a very costly bag of dead cells. This makes the process of proper storage, and shelf life utilization of biofertilizers, a hidden pivot upon which the entire biological fertility program is balanced, with implications that affect grower economics, their yield, and long-term soil health and restoration.

Preserving Microbial Viability for Peak Field Performance

- Temperature controlled storage: Products should be kept between 15 °C and 25 °C. CFU counts can be affected by 10% per week if above 35 °C or below 5 °C.

- Humidity controlled storage: Relative humidity should be kept under 60 %. Excess moisture will provide a conducive environment for the growth of contaminants and may initiate premature spore germination.

- Light controlled storage: Ultraviolet radiation can kill spores in a matter of days; opaque containers, and storage in rooms that provide shade is a non-negotiable principle of valid material biofertilizer storage.

- FIFO store rotation: Record the date upon arrival inside the shipping container and utilize the oldest product first. Viability declines over time; you want to be assured you deliver the complete microbial dose per hectare on every application.

Economic Pay-offs of Minimising Inoculant Losses

- Lower fertiliser costs: A properly preserved inoculant provides 20–40 kg ha⁻¹ of urea credit. If the CFU counts crash, that nitrogen "credit" dissipates and chemical costs return.

- Avoided reorder: Ordering an additive biofertiliser mid-season due to failure could easily be an added US $20–30 ha⁻¹ in incurred costs.

- Reduced fuel & labour: Reliable product sourcing avoids an additional, emergency run as another fertiliser (since there is no difference from a chemical). Diesel & the additional field time is reduced.

- Premium markets: Certification bodies routinely test CFU viability; if you pass a CFU audit the first time, you will receive premium prices with reduced exposures to penalty fees for exceeding CFU residual limits.

Soil-Health Dividends from Consistent Microbial Doses

- Steady nutrient cycling: When every application receives the CFU- counts guaranteed on the label, soils are provided a continuous trickle of biologically fixed N, solubilised P and mobilised K - adding fertility, not mining it.

- Humus accumulation: Living microbes produce polysaccharides that bind soil particles into stable aggregates, increasing organic- derived carbon by 0.1–0.3 % a year.

- Biodiversity enhancing: With consistent inoculations, you will stimulate beneficial fungi, earthworms and predatory nematodes, providing a self-reinforcing soil food web.

- Resilience to external pressures/stresses: Fields with healthy microbial live populations, have greater drought tolerance (better efficiencies of water retention under drought stress) and less disease pressure (buffering crops against pathogen outbreaks).

Understanding Biofertilizer Storage and Shelf Life

To ensure live inoculants are potent from factory to field, growers must be aware of and manage three invisible enemies: temperature fluctuations, random moisture, and unregulated oxygen. If any of these parameters exceed the safe limit for a specific carrier/format, the growing microbial population can drop below viability (⌂(≈10⁷ CFU g⁻¹ or mL⁻¹)), impacting yield and soil-health aspirations. Therefore, sound principles of biofertilizer storage begin with understanding how these stressors impact different carriers/formats.

Temperature Thresholds: Cold Shock vs Heat Stress

- Heat stress ( > 35 °C) initiates metabolism, burns internal stores, and denatures enzymes. A week on the floor of a tin shed could reduce viable counts by 30–50 %.

- Cold shock (< 5 °C) can rupture cell membranes, especially in liquid cultures; multiple freeze–thaw events can be fatal.

- A safe band (15–25 °C) protects 90 % viability for 9–12 months in most solid or liquid inoculants. For farmers in hot zones, insulated cool-rooms or passive earth cellars are worth considering for the long-term storing of biofertilizers.

Moisture & Oxygen Dynamics Inside Packaging

- Too much humidity in the solid carriers causes spore germination to be premature or leads to clumping; keep your storage room under < 60 % RH and use desiccant packets in opened bags.

- Low level of oxygen is key—strict anaerobiosis leaves aerobic strains without air to breathe—but too much O₂ oxides protects enzymes. One-way breather valves allow HDPE drums to keep gas flow in balance to protect liquid inoculants.

- Watch for condensation: humidity and moisture are significant — pallets placed directly on concrete draw moisture from the ground snow; pallets or hardwood strips should always be placed under bags to provide an air gap and keep unseparated biofertilizer conditions stable for storage.

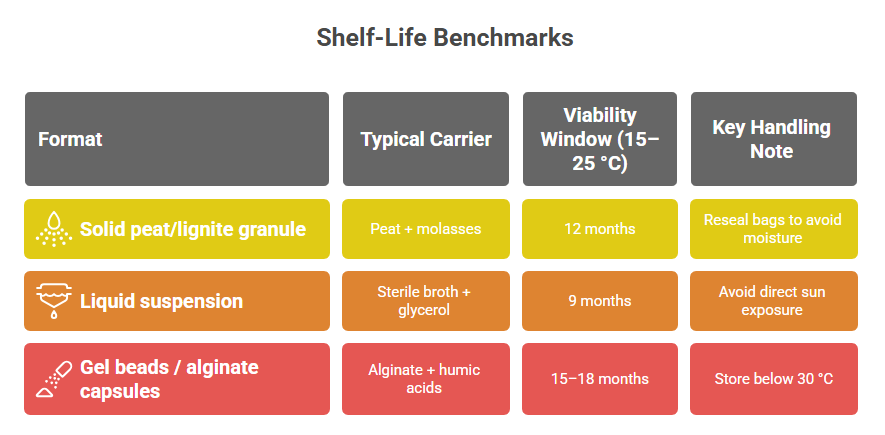

Shelf-Life Benchmarks for Carriers and Formats

Knowing these benchmarks lets growers plan procurement and application schedules so the microbes hit the soil at peak potency, not on life support.

Critical Factors in the Storage of Biofertilizers

Effective biofertilizer storage has less to do with high-tech buildings and more to do with disciplined basics: the proper container, a dependable rotation system, and swift in-house evaluation to confirm microbial viability. You lose sight of one of these essentials and even a room with climate control can become a place for bags of dormant (or worse, dead) cells.

Selecting Airtight, UV-Safe Containers

- Barrier protection: For liquids use opaque high-density polyethylene (HDPE) drums, and combat supplies should be in multi-layer foil or laminated kraft bags as these block ultraviolet radiation which can halve CFU counts in under two weeks.

- Moisture control: Manufacturer-sealed seams and moisture barrier liners to keep relative humidity under 60 % and reduce the chance of clumping or premature germination in peat or lignite carriers.

- Gas management: One way breather valves on liquid drums are adequate to allow fermentation gases to escape without allowing oxygen to gush back in: an important precaution for long-shelf-life suspensions. Selecting the appropriate container represents the initial (and most long-term) barrier in any strategy for long-term biofertilizer storage and the expected shelf life.

FIFO Rotation, Batch Dating & Inventory Logs

- First-In, First-Out (FIFO): Always use the oldest batch first; even under ideal circumstances, viability declines over time, so you should be using fresh products to fulfill orders.

- Batch dating: Every pallet and drum has a receipt date, as well as an expected field application date, on it—even simple masking-tape labels are fine, as long as they are updated.

- Digital logs: A simple spreadsheet or phone app that tracks batch numbers against storage location, and weekly room conditions allows you to conduct a quick audit of your available product and can prevent these costly redundancy orders. This orderly rotation satisfies that the biofertilizers stored are a living part of your operation and not a passive company liability collecting dust.

In-House Quality Checks: Simple Viability Tests

- First-In, First-Out (FIFO): Always use the oldest batch first; even under ideal circumstances, viability declines over time, so you should be using fresh products to fulfill orders.

- Batch dating: Every pallet and drum has a receipt date, as well as an expected field application date, on it—even simple masking-tape labels are fine, as long as they are updated.

- Digital logs: A simple spreadsheet or phone app that tracks batch numbers against storage location, and weekly room conditions allows you to conduct a quick audit of your available product and can prevent these costly redundancy orders. This orderly rotation satisfies that the biofertilizers stored are a living part of your operation and not a passive company liability collecting dust.

Best Practices for Biofertilizer Storage at Scale

Large operations often juggle multiple batches in different formats—peat granules, lignite pellets, and liquid suspensions. The table below contrasts two scalable layout options and highlights critical monitoring and contingency measures to safeguard biofertilizer storage and shelf life.

Take-home: A cool-room excels in hot climates or high-value liquid stocks; a retrofitted shed works for solids if weekly monitoring and shading are diligent.

Designing Cool-Room vs Field-Edge Shed Layouts

Weekly Monitoring—Temperature, Humidity, Light Exposure

Consistent checks are the cheapest insurance for long-term biofertilizer storage and shelf life. Set a recurring calendar alert—Monday morning, 10 a.m.—and run through three quick readings:

Record all values in a simple spreadsheet; six months of logs prove compliance for organic audits and help troubleshoot any field-performance dip.

Emergency Protocols: Backup Power & Mobile Insulated Chests

Even the best-designed facility can suffer power cuts or heat waves. A two-layer contingency keeps biofertilizer storage safe:

Implementing these quick-response steps ensures that unexpected events never derail months of careful biofertilizer storage and shelf life management. With disciplined monitoring and solid backup plans, every microbe arrives in the soil alive and ready to work.

Preventing Losses: Extending Biofertilizer Storage and Shelf Life

Regardless of how well an inoculant is made, it will be of little value if the microbes all die in the shed. Extending the shelf life of biofertilizer is about protecting each viable CFU from moisture spikes, oxidative stress, and light that will silently kill viability long before you recognize a lowering yield in the field. You can limit storage loss of biofertilizer to less than 5% for a complete season, even in challenging climatic conditions, if you can leverage just a few low-cost safeguards.

Desiccants, Oxygen Scavengers & Light Barriers

- Moisture control: Silica-gel packets placed inside opened bags will absorb ambient humidity, preventing premature germination of spores and clumping in peat or lignite carriers. Recharge silica-gel packets weekly in a low oven (≈ 60 °C) and put back in inventory (it is possible to have a 20% machine error during this process).

O₂ scavenger sachets located inside HDPE drums reduce oxidative stress on liquid cultures, especially important when drums are opened and closed – limit cycles where possible.

- Light protection: Opaque liners or foil-laminated bags reduce UV light damage that could half viable counts in 2 weeks. If you are using clear jerrycans for transportation, wrap them in tightly-closed black garbage bags to provide an immediate light barrier during storage of biofertilizers.

Field-Edge Tips for Tropical & Remote Farms

- Lifting pallets off the ground on wooden slats, will help prevent moisture from traveling into bags; condensation laying on a concrete floor can raise RH in specific locales to over 80 % overnight.

- By using shade cloth plus ridge ventilation, you can lower shed temperatures, 4–6 °C, than bare tin roofs - often low enough of a difference to stop the transition from healthy microbes to heat-stressed microbes.

- Mobile coolers supplied by 12 V batteries or ice bricks can serve to protect small amounts of liquids while being transported to remote plots; the goal should be keeping a product cold below 30 °C for the entire time.

- If no data-logger available then rotation, once/month or so, will do; if a stack completely covers a forgotten pile and is always moving, then whatever hasn't been used likely isn't going out of specification; and constantly moving the stack encourages FIFO discipline, especially for long term biofertilizer storage and shelf life.

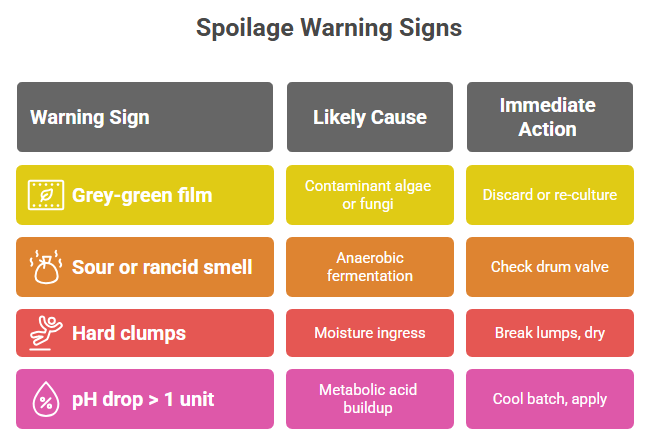

Recognising Early Spoilage—Colour, Odour, Clumping, pH Drift

Spotting these changes early lets you triage stock before it hits the planter, avoiding the hidden cost of applying dead inoculant and then compensating with extra synthetic fertilizer.

FAQs — Quick Answers on Biofertilizer Storage

Q 1. What is the safest temperature band for year-round biofertilizer storage?

Keep inoculants between 15 °C and 25 °C; this band preserves ≥ 90 % viability and maximises overall biofertilizer storage and shelf life.

Q 2. Can I keep liquids and solids in the same room?

Yes—if the room stays within the 15–25 °C, < 60 % RH targets and containers remain sealed, mixed-format storage of biofertilizers is safe.

Q 3. Does sunlight wreck biofertilizer storage and shelf life?

Direct UV light can halve CFU counts in two weeks, so always use opaque drums or dark rooms to protect stocks.

Q 4. How do I know when the storage of biofertilizers has failed?

Watch for sour odour, discoloured film, hard clumps, or a CFU plate count below 10⁷ g⁻¹/mL⁻¹—any one signals ineffective product.

Q 5. Are desiccant bags useful for every package?

Absolutely; silica-gel packets in opened bags or drums absorb moisture spikes and extend biofertilizer storage and shelf life by several weeks.

Conclusion: Mastering Bio Fertilizer Storage for Sustainable Yield

Every litre or kilogram of inoculant is a living asset; one that can create profits and soil health, or a costly bag of dead cells. The only thing separating a valuable and effective biofertilizer from a costly inoculant is the practice of disciplined storage of biofertilizers. Absorbent inert material with maximum temperature storage exposure in the 15 – 25 °C safety band, humidity under 60 %, don't expose to UV light from tape or use paper or opaque containers. Use a First In First Out (FIFO) management system. Use low-cost additional protective measures like desiccant packs, oxygen scavengers, and fast plate-count tests. Rugged storage and shelf-life extended well past expiry dates allows not only budget saving for farmers in synthetic-fertiliser input contracts, but also continuous betterment in microbial delivered shipping of CFU's, intermittently enhancing soil structure, organic carbon, and water holding ability in soil. Effective management of the practical storage of biofertilizers provides assurance that the microbes you paid good money for will be safely protected, allowing reliable yields and a pathway towards genuine farm sustainability.